ANSYS

ANSYS is a powerful engineering simulation software used for analyzing and solving complex engineering problems. It is widely used for Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), thermal analysis, and electromagnetic. ANSYS helps engineers simulate how a product will perform in real-world conditions before manufacturing. It reduces the need for physical prototypes, saving both time and cost. Industries like aerospace, automotive, civil, electronics, and biomedical use ANSYS extensively. Engineering students use ANSYS to visualize stress, strain, heat flow, fluid motion, and electric fields. It supports innovation by allowing students to test their designs digitally and improve them efficiently. ANSYS provides hands-on experience with tools used in professional R&D and product design. Knowledge of ANSYS enhances a student’s resume and employability in core engineering sectors. Learning ANSYS bridges the gap between theoretical concepts and practical applications in engineering.

Solid Works Software

Solid Works is a powerful computer-aided design (CAD) software widely used in engineering and product design. It allows users to create 2D drawings and 3D models with high precision and efficiency. Engineering students benefit from SolidWorks by gaining practical skills in designing mechanical components, assemblies, and simulations. The software supports parametric design, making it easier to modify parts and assemblies based on specific requirements. Solid Works is also equipped with simulation tools that help analyze stress, motion, and fluid flow, enhancing students’ understanding of real-world engineering problems. It is commonly used in industries like automotive, aerospace, manufacturing, and robotics. By using SolidWorks, students learn to interpret engineering drawings and create models that meet industry standards. It encourages innovation and problem-solving by allowing iterative testing of designs. Many universities include Solid Works training in their curriculum to make students industry-ready. Overall, Solid Works serves as a vital tool for developing technical, analytical, and creative skills in engineering education.

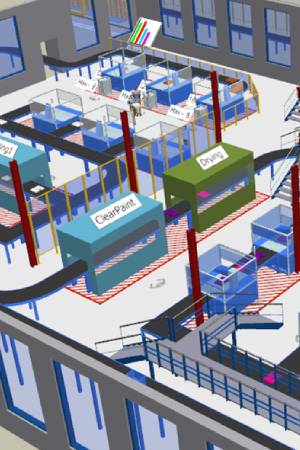

Technomatic Plant Simulation

Technomatic is a multidisciplinary platform that integrates advanced technologies such as automation, robotics, artificial intelligence, and mechatronics to support innovation in engineering. It provides engineering students with hands-on experience in designing and implementing real-world industrial solutions. Through the use of programmable logic controllers (PLCs), sensors, actuators, and simulation tools, students gain practical skills in system integration and control. Technomatic is widely used in manufacturing, automotive, aerospace, and smart infrastructure sectors. It bridges the gap between theoretical knowledge and industrial applications, making learning more relevant and engaging. Engineering students use Technomatic to develop projects, perform system diagnostics, and optimize production processes. It encourages creative problem-solving and teamwork by simulating real-time challenges. With Technomatic, students are better prepared for Industry 4.0 demands. It also fosters research and development in areas such as IoT and intelligent automation. Overall, Technomatic empowers students with future-ready skills essential for success in modern engineering careers.

Competitive Examination classes

Competitive examination classes arranged by the Mechanical Engineering Department play a crucial role in shaping students’ academic and professional futures. These classes prepare students for exams like GATE, IES, SSC-JE, and various PSU recruitments. They help in strengthening core engineering concepts, problem-solving abilities, and time management skills. By providing expert guidance and regular practice tests, these classes boost students’ confidence and exam readiness. They also expose students to the latest exam patterns and frequently asked questions. Apart from academic preparation, these sessions motivate students to aim higher and stay focused on their career goals. The department’s initiative ensures that even academically average students get the right support to compete nationally. Regular doubt-solving and performance analysis help students improve steadily. These classes often include career counseling and strategic planning for government and higher education opportunities. Overall, such efforts enhance the employability and competitiveness of mechanical engineering students.